Because of Covid 19, businesses have faced unprecedented and potentially life-threatening challenges. This has highlighted the...

Budgeting and planning activities within companies are often time-consuming and quickly outdated in their significance. Methods like driver-based planning or even Beyond Budgeting represent attempts to increase efficiency, but the approach remains old-fashioned. However, the developments in the field of AI/ML are now opening up completely new possibilities. In the near future, it will be possible to calculate and compare a wide variety of planning scenarios within minutes.

1. Introduction

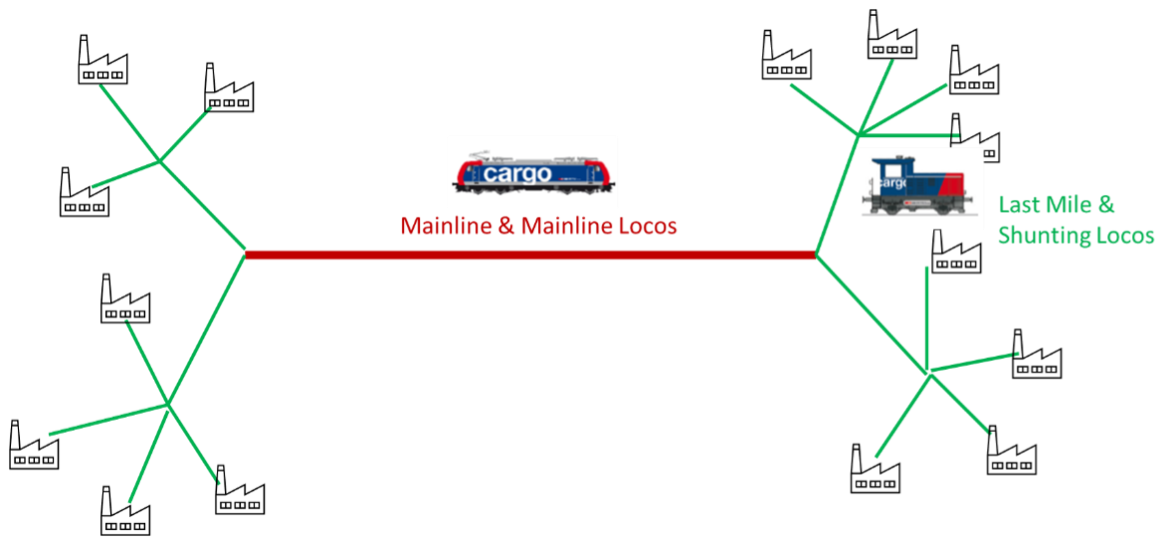

At SBB Cargo, the system for wagonload traffic consists of two separate production lines. Firstly, there are the mainlines over longer distances between shunting yards, which are now operated with so-called mainline locomotives. Then there is the last mile, i.e. the collection and delivery of wagons between loading points and team stations. This is handled by shunting locomotives.

Figure 1

SBB Cargo is currently faced with a question: Should the company continue using two types, - mainline and shunting locomotives -to replace the locomotive fleet? Or should a uniform solution be purchased for both the main runs and the last mile, i.e. an "all-in-one"-solution?

What seems relatively simple at first glance turns out to be a complex problem in practice. The change to one single locomotive type will change all route plans - not only the round trips of the locomotives, but also the operating times of train drivers and shunting staff, the slots of the available tracks, and finally the pick-up and delivery times at the customers.

The solution space for such a new production concept is infinitely large, and the effort is already very high for a single planning scenario. This means that decision-making can only be supported very poorly with conventional planning instruments.

2. New approach: “Digital Twin”

To solve the above problems in a quick and adequate way, we have decided to map the business model using a “Digital Twin”. The objectives are:

- Providing fast and well-founded answers to strategic and tactical questions

- Automation of financial planning and forecasting processes

- Automation of operational planning and scheduling/dispatching processes

- Entanglement between financial and operational planning systems

The fascinating thing about this approach is that the creation of the digital twin does not build on abstracting and simplifying the business by drivers or other methodologies, but by digitally replicating the effective business processes and rules. This not only allows an application directly within the daily operational processes; it also offers the possibility to digitally run through a wide variety of scenarios simulating their effects, i.e. to plan them.

We are currently seeing some successes and progress in the development of the digital twin, but in certain areas, there are still challenges to solve. Let’s have a look at our process landscape:

.png)

Figure 2

For example, the following functions have already been implemented and used:

1. Automated locomotive circulation planning

2. Automated route planning for train drivers

3. Automated staffing of train drivers on the tours

4. Automated re-routing of shipments in the event of route closures or interruptions

5. Strategic simulation of logistics networks for different shipment scenarios

The challenges include:

1. The predictive forecasting algorithms still require too many inputs from Key Account Management. The handling for daily use is therefore still too cumbersome.

2. In the area of the last mile, there is still a lack of sufficient operational data, so abstract models have to be used there.

3. Regarding the simulation and automation of wagon circulation, there is still a lack of applicable mathematical models, so we work directly with universities in this area.

4. The link of locomotive and train driver regular planning to daily scheduling/deviation is still an open issue.

And finally, it should be emphasised that all these models can only be developed and put into operation if the specialists in the triangle of IT, mathematical modelling, and business work closely together. In hectic times especially, business specialists are often so absorbed by the daily work that they have too little time to deal with developments and new instruments.

3. Benefits of such models

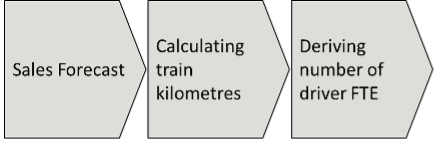

To explain the usefulness of this model, we consider train driver planning as an example. So far, train driver planning has been driver-based:

Figure 3

Based on an aggregated sales forecast, the train kilometres were derived, and the number of necessary train drivers was calculated. This methodology was simple, easy to understand, quick to implement, and showed a precision of 80 to 90% - from a bird's eye view.

However, this form of planning did not allow any statement to be made about under- or overcapacity per train driver depot, or about necessary driver skills. The train drivers are organised in individual depots, where they are distributed to the specific trains, provided, they bring in the driving skills for the required routes. Each train driver must be able to prove specific knowledge of the route, which means that not every train driver can be used on every tour. With the simplification of driver planning, the individual depot managers do not yet know whether they must hire train drivers, train them on new sections, or sublet them to other transport companies. This will only become apparent later when the orders for specific tours come in.

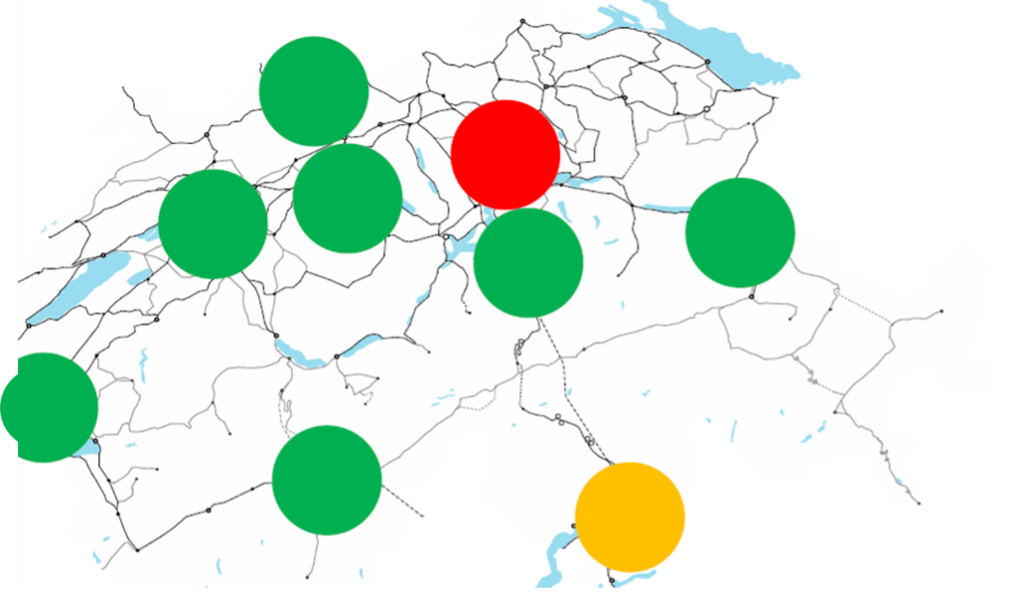

The "Digital Twin" for train driver planning now captures all train driver depots, including the drivers employed there, with their corresponding driving skills.

Figure 4

On the basis of the train timetables, the Twin can now immediately define the train driver tours and staff the existing employees. This classification not only shows how many train drivers are needed. It also shows whether, and in what number, over-or under capacity or training requirements are found in specific depots. The action plan for every depot manager is thus immediately apparent.

Another advantage is that specific depots can be geographically moved, opened, or closed for tactical issues, and the Twin can calculate how many train drivers this will require. With this instrument, the planning is not only automated and improved in terms of content, each manager also receives their need for action directly, and the development department can simulate any scenarios within a reasonable time period.

This small example also demonstrates that a benefit from such a "Digital Twin" does not only result when the business model is fully mapped but already with each individual model.

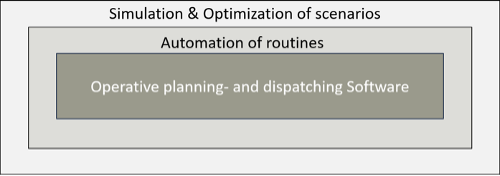

4. Implementation effort

Benefits aside, decision-makers must of course ask whether the effort of implementing such twins is worthwhile, or whether classic planning processes suffice. Ultimately, every company must answer this question itself. But if a company has to rely on essential IT systems in operational planning and scheduling processes to fulfil its services, then those competitors who can automate and even simulate these processes will gain efficiency advantages. It is also often much more complex to implement the core systems as the elements for automation and simulation afterwards.

Figure 5

In addition to this pure cost analysis, there is another exciting element in the implementation. While introducing IT systems normally results in a partnership between IT programmers and business specialists, the "mathematical modeller" now appears on the scene. To implement functioning and effective simulation models and optimisers, the mathematical modeller must not only understand the business, there should also be as few restrictive business conditions or special cases as possible. If this fruitful discussion between mathematics and business is allowed, a welcome byproduct is the opportunity to simplify and standardise processes.

5. Result

The world and thus also business usually consist of complex systems. The handling of such systems and their reaction to various events is rarely easy to predict. The FP&A function works to abstract and simplify this complexity – but, on rare occasions, it won’t be possible to derive concrete potentials or action activities.

With today's computational and mathematical possibilities, however, you no longer have to shy away from complexity. Instead, you can digitally reproduce the actual business processes. This not only opens up automation and simulation possibilities, but also the immediate implementation of optimisation measures in the daily operational processes. After all, those who manage to implement their findings for optimisation into operational execution can gain competitive advantages.

Subscribe to

FP&A Trends Digest

We will regularly update you on the latest trends and developments in FP&A. Take the opportunity to have articles written by finance thought leaders delivered directly to your inbox; watch compelling webinars; connect with like-minded professionals; and become a part of our global community.